The TS-100 is a professional, semi-automatic stand-alone tray sealing machine with vacuum and gas flushing (MAP) – also suitable for gas flushing with oxygen (optional). It ensures an optimal shelf life for the packed products with minimal gas usage. Offer your customers a fresh packing service and watch your sales grow.

| Technical detail: | ||

| Vacuum pump (cbm/h): | 40 (63, 100) | |

| Top film width (mm): | 422 | |

| Film core diameter (mm): | 70–76 | |

| Maximum tray depth (mm): | 95 (150) | |

| Maximum tray sizes (mm): | 300 x 380 | |

| Outer dimensions (w x l x h/mm): | 540 x 980 x 1000 | |

| Loading hight (mm): | 970 | |

| Compressed air consumption (l/cycle): | 6 at 6 bar | |

| Maximum diameter of top film (mm): | 330 | |

| Power connection (v/ph/Hz): | 400/3Ph+N+PE/50Hz | |

| Power (kW): | from 3 | |

| Weight (kg): | 235 (240, 260) |

Standard Equipment

Options

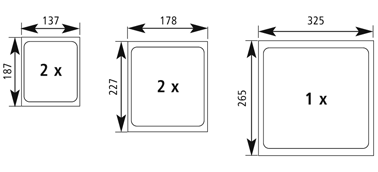

Standard tray sizes:

137 x 187 mm, 178 x 227 mm, 325 x 265 mm

The TS-100 is a professional, semi-automatic stand-alone tray sealing machine with vacuum and gas flushing (MAP) – also suitable for gas flushing with oxygen (optional). It ensures an optimal shelf life for the packed products with minimal gas usage. Offer your customers a fresh packing service and watch your sales grow.

| Technical detail: | ||

| Vacuum pump (cbm/h): | 40 (63, 100) | |

| Top film width (mm): | 422 | |

| Film core diameter (mm): | 70–76 | |

| Maximum tray depth (mm): | 95 (150) | |

| Maximum tray sizes (mm): | 300 x 380 | |

| Outer dimensions (w x l x h/mm): | 540 x 980 x 1000 | |

| Loading hight (mm): | 970 | |

| Compressed air consumption (l/cycle): | 6 at 6 bar | |

| Maximum diameter of top film (mm): | 330 | |

| Power connection (v/ph/Hz): | 400/3Ph+N+PE/50Hz | |

| Power (kW): | from 3 | |

| Weight (kg): | 235 (240, 260) |

Standard Equipment

Options

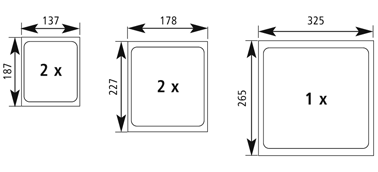

Standard tray sizes:

137 x 187 mm, 178 x 227 mm, 325 x 265 mm